|

Electric Sieve Electric

Stainless Steel Powder Shaker

|

||||||||||||||||||||||||||||||||||||||||||

|

GENERAL SAFETY PRACTICES |

||||||||||||||||||||||||||||||||||||||||||

|

WARNINGS: 1. Prior to operate the laboratory test sieve shaker , please make sure all the components are fastened, no broken on the sieves, no damage on the machine, electrical cables are connected properly. 2. Power supply is the same as shown on the machine plaque. (Tolerance for voltage is +/- 10%) 3. Keep all parts in place at all times to avoid exposure to parts rotating at high speeds. While the power is on, severe injury can occur if hands or feet reach inside the unit. 4. When installing or maintaining this instrument, shut off and lock out power. Follow all local and national electrical codes. Failure to do so could result in severe personal injury or property damage. 5. Higher amplitudes occur during shut down and start-up of unit. Stand clear of unit and keep accessory equipment away during these cycles.

CAUTIONS: 1. Securely tighten all nuts and bolts on the unit. Pay special attention to the motor mounting bolts. If a motor vibrates loose, damage to the power cord and to the structure may result as well as risk of personal injury. 2. Do not operate instrument with more than quantity of weight we recommended. Overloading the top and bottom weight assemblies will place excessive load on motor bearings which can cause permanent damage to the motor and to the instrument. 3. Never run motor with weights exposed. Failure to do so could result in severe personal injury or property damage. 4. Screens are fragile. Handle with care. Never place tools or parts on the screen or damage to screen may occur. 5. The noise level produced by this equipment may not be acceptable to your environment. Take every precaution to make certain that safe noise levels are met.

|

||||||||||||||||||||||||||||||||||||||||||

|

INTRODUCTION |

||||||||||||||||||||||||||||||||||||||||||

|

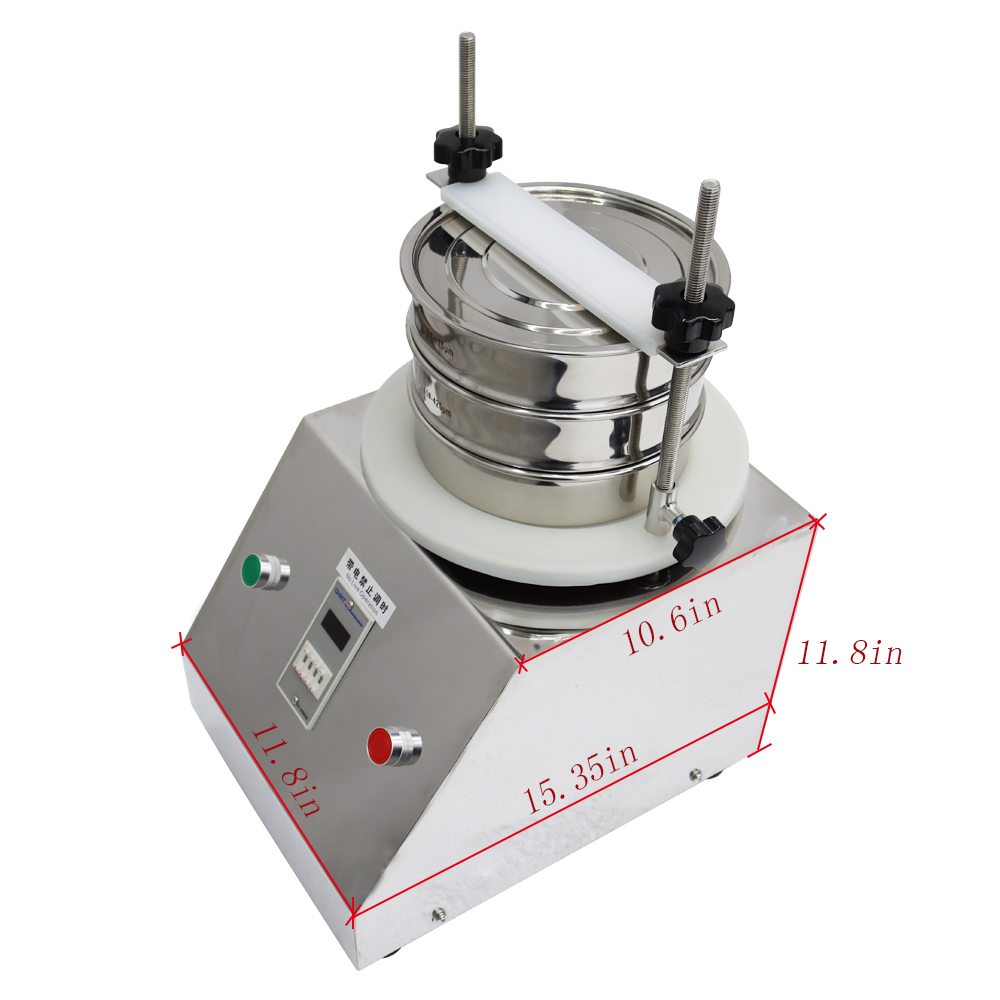

Usage: TH-200 is suitable for particles distribution analysis of grains, powder or the solids content test of liquid in laboratory and Quality Control Department. It has features of low noise, high efficiency andprecision.

Working Principle: Features:

Digital Timer/Clock:

|

||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||

| Necessary parts: Main item, cover, bottom pan, sieves with required mesh Cover: Stamped or spun lid that tightly covers the top of a sieve to prevent the loss of the material sample during sifting or mechanical agitation. Screen frame: A rigid sidewall used to form the body of the testing sieve. Common depths are 50 mm (full height).

|

||||||||||||||||||||||||||||||||||||||||||

|

TECHNICAL PARAMETERS |

||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||

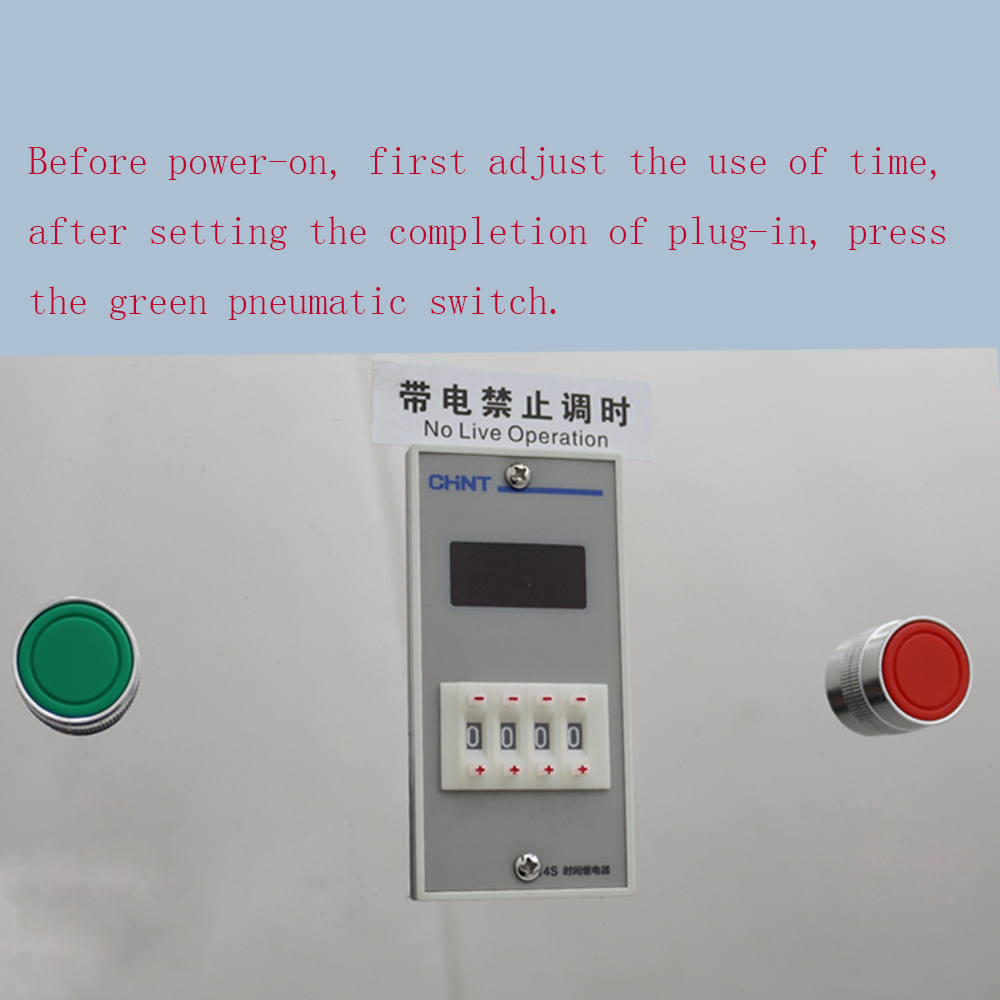

| HOW TO SET THE TIMER | ||||||||||||||||||||||||||||||||||||||||||

| Electrical Connection Plug the power cord into the socket in the rear of the unit and then into the appropriate power source as outlined in the specifications section. |

||||||||||||||||||||||||||||||||||||||||||

| Setting and using the

timer Press the small button to turn on the digital display. Continue to press the timer button until the desired sift time is shown in the digital display. The timer can be set between 1 second and 99 minutes. |

||||||||||||||||||||||||||||||||||||||||||

| Starting and stopping

the timer Red button ------- stop Green button ------- start When you set the time after press the green button, the unit will begin to operate until the setting timing is up. |

||||||||||||||||||||||||||||||||||||||||||

| Pausing and resetting

the timer If desired, the instrument can be paused at any time during the cycle by pressing the red button. It can be restarted to finish the remaining portion of the cycle by pressing the green button. To change the preset program time, first press the red button to make the machine stop. Then, reset the digital to the desired time and press the green button and the machine will go on. |

||||||||||||||||||||||||||||||||||||||||||

| HOW TO OPERATE | ||||||||||||||||||||||||||||||||||||||||||

|

Before using: |

||||||||||||||||||||||||||||||||||||||||||

|

Using: A. Plug the power cord into the socket B. Setting the required time C. Switch the start button and the unit starts to work until the setting time is up. D. Switch the button to stop the machine during the working process as needed or reset the time as needed.

|

||||||||||||||||||||||||||||||||||||||||||

| After using: A. Turn off the power B. Clean the screen after operation, place the machine in the right place. |

||||||||||||||||||||||||||||||||||||||||||

| Note: A. Turn off power supply when the machine is not in use for an extended period of time. B. The screen after operation, so they will be ready for use next time. C. Do not splash water on the machine to avoid current leakage. D. Turn the machine off immediately in the event of unusual noises and inspect for blockage or other irregularities. E. Always ensure the hand shank and tight handle are securely tightened before operation. F. Control vibration force as needed by increase or decrease the balance weight on vibration motor. |

||||||||||||||||||||||||||||||||||||||||||

|

Item Number:

Electric Sieve Electric

Stainless Steel Powder Shaker -230235

|

||||||||||||||||||||||||||||||||||||||||||

|

You can make order with

no worry. |

||||||||||||||||||||||||||||||||||||||||||